Business Sites Initiatives

Business Sites Initiatives

Initiatives at Casio (Thailand) Co., Ltd.

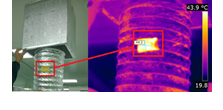

Using insulation to reduce energy use

The company reduced the air-conditioning cooling load by installing insulation around the exhaust ports of the reflow system and dryer to block heat conduction and this has helped to reduce greenhouse gas emissions.

Reflow systems insulation

Before installation

(surface temperature 44.2C)

After installation

(surface temperature 21.9C)

Surface temperature decreased from 44.2°C to 21.9°C.

Introducing buses to reduce CO2 emissions

The company has 40 buses that it provides for employees to use for their daily commute. Employees use these commuting buses and this has helped to reduce greenhouse gas emissions.

Commuting buses at Casio (Thailand)

Installing a unique solar system

Casio (Thailand) has installed its own photovoltaic system to take advantage of the tropical sunlight. Electric power generated by the solar panels is used to power electric roof fans to draw heat out of buildings, as well as for powering daytime lighting in a warehouse and agitating a reservoir for oxygenation.

Electric rooftop exhaust fans for heat discharge

Daytime warehouse lighting

Reservoir agitator for air circulation

Initiatives at Yamagata Casio Co., Ltd.

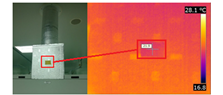

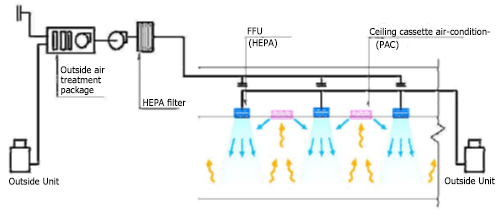

Introducing the latest energy-saving air-conditioning systems

A new watch plant that started operations in May 2018 uses the latest energy-saving air-conditioning systems, such as an air-conditioning system with several air-conditioners with FFUs*1 and ceiling cassettes, zoning and separate air-conditioning for clean rooms. These systems enable efficient operation according to the production situation.

*1 FFU: Fan-filter unit. A system that passes air sucked in by the fan through a filter to purify it before sending it out as clean air.

Air-conditioning system at Yamagata Casio

Clean room with latest air-conditioning system

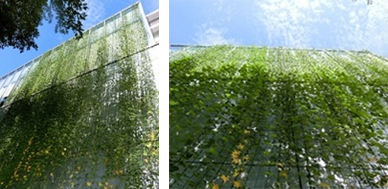

Initiatives at Hachioji R&D Center

The Hachioji R&D Center has installed automatic blinds and grows a green wall of vegetation at its facility to reduce CO2 emissions. The automatic blinds calculate the location of the sun, use sensors to detect the strength of the sunlight, and open and close automatically, thereby reducing the cooling and heating load. Since 2012, the Center has also grown a green wall of vegetation as a summertime energy-saving measure in an effort to reduce the cooling load even more. Through a process of trial and error to balance watering, fertilization, and sunlight, currently, the green wall (planted with two kinds of morning glories) grew splendidly to a size of 8.5 meters wide by 10 meters tall. Local residents even stopped by to take photos of it. This initiative to grow a green wall of vegetation has entered Hachioji’s Green Wall of Vegetation Contest in the “organization grouping” since 2017 and won awards two years running, including the first place award in 2017.

Green wall of vegetation at the Hachioji R&D Center

Award certificate and first place gift

Installation of LED Lighting

Casio is installing LED lighting at its business sites to reduce electricity consumption. Thus far, it has installed LED lighting at many Casio sites, including the Hatsudai Head Office, Hamura R&D Center, Hachioji R&D Center, Yamagata Casio, Casio Electronics (Shenzhen) Co., Ltd., Casio (Thailand) Co., Ltd., Casio America, Inc., and Casio Electronics (Shaoguan) Co., Ltd., and other sites. The installed LED lighting has brought about substantial CO2 emissions reductions.

LED lighting in Casio Electronics (Shenzhen)’s lobby

LED lighting in Casio (Thailand)’s plant

LED lighting in Yamagata Casio’s plant